Federal Express Corporation (FedEx), the world’s largest express transportation company, has introduced its first AI-powered robotic sorting arm in Europe at its Cologne air network facility, marking a significant step in digitizing its operations and building a smarter logistics network.

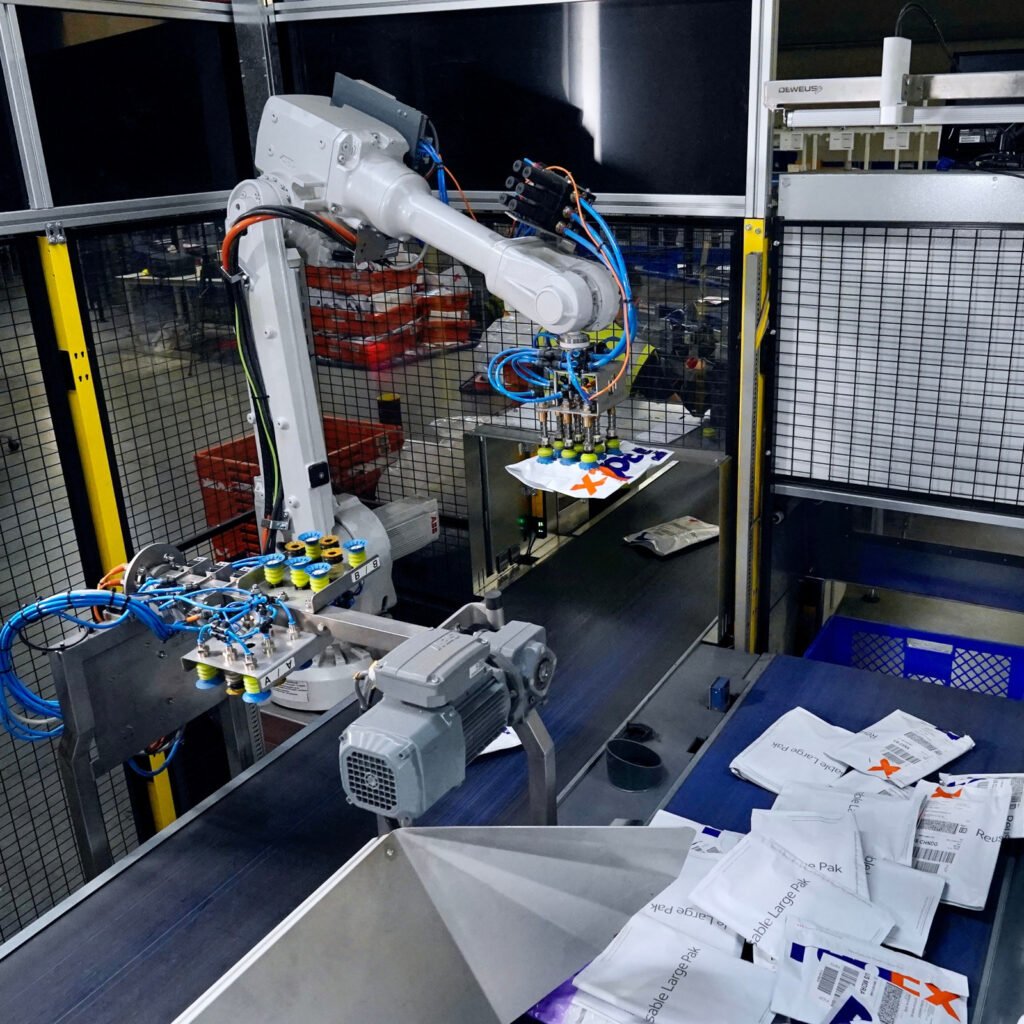

The robotic arm, developed by Hellebrekers B.V., is installed within a protective cage at the small package sorting area of the Cologne hub, the largest of FedEx’s seven air network facilities in Germany, which employs over 900 workers. Capable of processing up to 1,000 documents and parcels weighing up to 4kg per hour across 90 destinations, the robot streamlines sorting tasks, allowing employees to focus on more complex duties.

“AI-driven technologies like this robotic arm enable us to handle shipments more efficiently, enhance customer satisfaction, and strengthen our competitive position as e-commerce fuels market growth,” said Boris Stoffer, Managing Director of Network Operations for Germany at FedEx. “These tools also reduce physical strain on our team by automating repetitive, high-volume tasks.”

ALSO READ:EUTELSAT LAUNCHES ONEWEB EARTH STATION IN ANGOLA

Georgiana Constantin, Manager of Planning, Engineering Innovation, and Properties Design at FedEx, added, “This robotic in-feeding system underscores our commitment to innovation and delivering best-in-class service, driven by a passion for putting customers first.”

The Cologne initiative aligns with FedEx’s global automation efforts, which began in 2020 with the installation of four robotic arms at its Memphis Hub in Tennessee.

The company expanded its robotic sorting capabilities in 2022 at its South China E-Commerce Shipment Sorting Center in Guangzhou and its Singapore Hub. Additionally, FedEx operates robotic product sortation and identification systems at 17 U.S. facilities, including locations in New York, Las Vegas, and Ohio.